The average customer entering your gun store has a very narrow focus. They are often interested in one item that you sell. You can bet they have already scoured the internet and learned all they can about it before you see them.

When they come in, they expect that the person helping them will be as knowledgeable as they are and will be able to answer their remaining questions. The difficulty is that while they are focused on one item, you must know about a broad range of products and topics. You must have the correct information because the internet contains at least as much drivel as facts.

You're not alone if you don’t know about annealing brass. Many long-term reloaders are only remotely familiar with the process and why it would be used. That’s OK. It doesn’t take long to understand the topic and learn how to explain it to your customers.

Original Character

Once upon a time, rifle cartridge cases were made of copper rather than brass as they are today. The conversion to brass happened in the late 19th century for several reasons. It was cheaper, more easily formed, and less corrosive. One reported issue was that copper cases corroded in leather bandoliers. When they were fired, the copper expanded, and the corrosion caused the cases to stick in the chamber. There are numerous historical accounts of copper cartridges causing extraction issues. One of the more colorful ones comes from Pvt. William Slaper from the 7th Cavalry at the Battle of Little Big Horn (1876), often called Custer’s last stand.

“While in this line, Capt. French was about in the center, giving orders as coolly as though it was a Sunday school picnic. He would sit up Tailor-style while bullets were coming from the front and both sides. I could but marvel that he was not hit. Without appearing to be in the least excited, he would extract shells from guns in which the cartridges would stick, and pass them loaded, then fix another, all the time watching in every direction.”

By 1888, the military officially switched to brass cartridge cases. Brass is more resilient and less prone to corrosion. In addition, when fired, a brass case will expand to fill the chamber but spring back close to its original size afterward, making it less likely to have extraction problems.

Brass is an alloy of copper and zinc. The percentage of zinc added determines the characteristics of the alloy. Typically, brass used in cartridge cases comprises 70% copper and 30% zinc. This ratio provides the right combination of malleability and strength, making it the ideal choice. Like all metals, folding, stretching, hammering or forming causes a condition called “work hardening.” The more it is worked, the harder (and more brittle) it becomes. This is a problem since creating a cartridge case requires much work. To counter this effect, manufacturers use annealing to restore the brass to its original (softer) character.

Annealing brass makes it softer and more malleable, but it’s not the entire case that’s annealed. Only the neck and shoulder area of the case is softened. This is because the main body and base must be harder than the mouth and shoulder area. Typically, the body is about twice as hard as the open mouth area. That strength permits the case to withstand the high pressures typical to rifle cartridges.

Watch the Heat

Annealing is another way of saying that the metal was heated in a controlled fashion to remove internal stresses and make it easier to form. You can’t just randomly heat the brass. It must be heated enough to cause the metal to soften without overheating, making it too soft. The main factor is the zinc in the metal. Copper melts at about 1700° Fahrenheit. Zinc melts around 790°F. If heated above 790°, the zinc will start burning off, changing the metal’s structure and making it softer. Too much heat and the brass will become unusable. The question becomes, how do we know if it is overheated?

Reloaders used to rely on two fundamental observations. If heated above 790° F, the flame used to heat the metal will take on an orangish color as the Zinc is burned off. The other indicator is the brass itself. If it’s allowed to heat to the point where it glows, it has exceeded the required temperature and should be thrown away. It will be too soft to use. There are more sophisticated and accurate methods today. The first is to use an infrared thermometer to measure the brass temperature. These are accurate and easy to use. They are also relatively inexpensive. Another popular method is to use a temperature-specific paint such as Tempilaq. Tempilaq has many different formulations which melt at different temperatures. I use the Tempilaq 750° paint. A dab of paint inside the case mouth is all it takes. It will melt once the case temperature reaches the specified temperature.

We’ve already seen that the body and base of the case should not be annealed. Many reloaders submerge the case body in a pan of water before heating the case mouth with a torch. The water kept the heat from affecting anything except the shoulder and neck. Today, many people use Tempilaq 450° F. They paint a mark just below the case's shoulder and ensure that heat never reaches it. If it does, the lower-temperature paint will melt. Some insist that the case must be quenched immediately after annealing. While this is true for other metals, it’s not for brass. Once the brass is heated, the annealing process is accomplished. It can be quenched, but it’s not required. The point is the heating rather than the cooling.

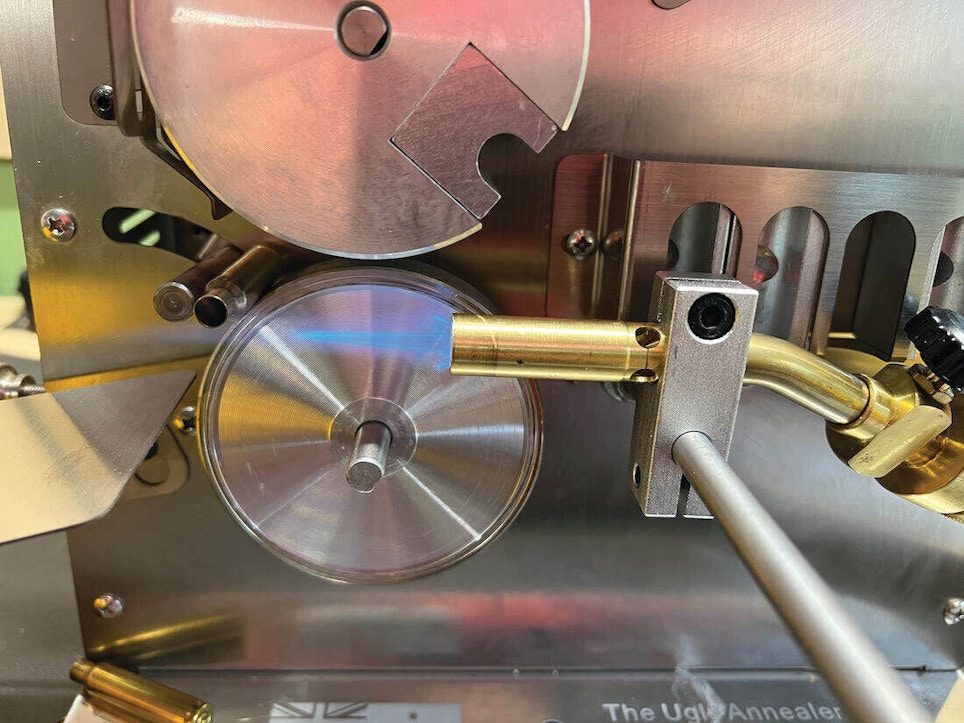

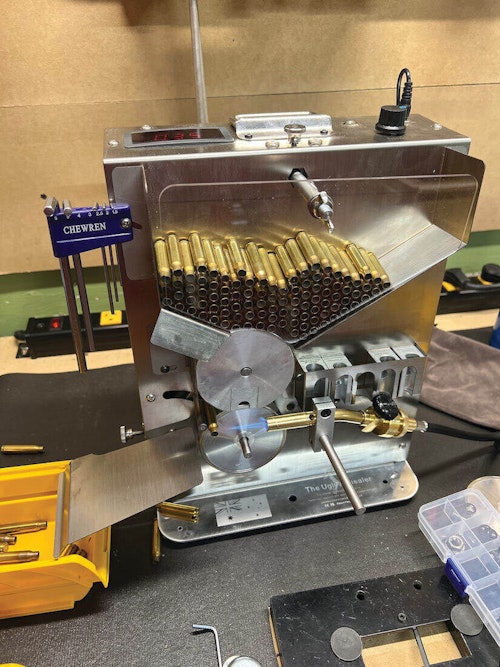

I’ve learned about people who have done their annealing with nothing more than the flame of a candle. I’m not that controlled or patient. Thankfully, machines are available to automate the process. I recently purchased “The Ugly Annealer” and am pretty pleased. After adjusting it properly, filling up the hopper with brass is all that’s required. The machine will then do all the work. Several other manufacturers make similar machines. I can’t speak for those, although they operate on the same principle. The Ugly Annealer is the only one I have experience using. More expensive (and some say better) machines are available for those with deeper pockets than I have. One is the Annealing Made Perfect unit. I’m told that it is highly consistent and adaptable to multiple calibers. Some might need something more than my chosen unit, but I’ve found that mine covers all the calibers I shoot.

No Absolute Limit

Some ask if annealing is necessary. It is possible to reload brass several times without annealing. People do it all the time. It just means the brass will become brittle and split much sooner than if it was annealed. There’s no absolute limit to the number of times cases can be annealed. It doesn’t harm the brass, so there’s no reason not to anneal. Most people say they anneal their cases between the third and sixth shots. For people who create one caliber by forming it from the case of another caliber, annealing is more critical.

For example, I cut 223 Remington brass and then form it into 300 Blackout. Annealing is necessary to soften the brass for use. The area holding the bullet is shaped from the body of the .223 case, which formerly needed to be harder and stronger. Since it now must be shaped to hold the bullet, it must be treated with the softening process. Annealing before the brass is resized makes it easier and more consistent.

I’m sure you’ve seen bullets where the case mouth is discolored. That’s a sign that it was annealed. Don’t worry if you don’t see that indicator. Most manufacturers polish their brass after annealing to remove the discoloration. Polishing is not necessary. It just makes the cases look more visually appealing. There is no functional purpose behind it.

Share the Knowledge

The above information helps explain annealing so that you can easily remember and convey it to your customers. After all, you’re as much of a teacher as you are a salesman. Your ability to relate technical issues in plain English is one of the most crucial skills you can have. It does no good to have specialized knowledge if it’s only understandable to people who already know it. Just ensure that you keep learning new topics. You’ll become a trusted source in your local gun community. That will be good for your business and your customers.